Analytical Lyo Instruments

To successfully develop freeze dried formulations and products, companies need to assess the performance of these across many variables, including temperature, stability and structure. But analysing this effectively can be challenging – particularly without the right instruments for precise measurement and examination.

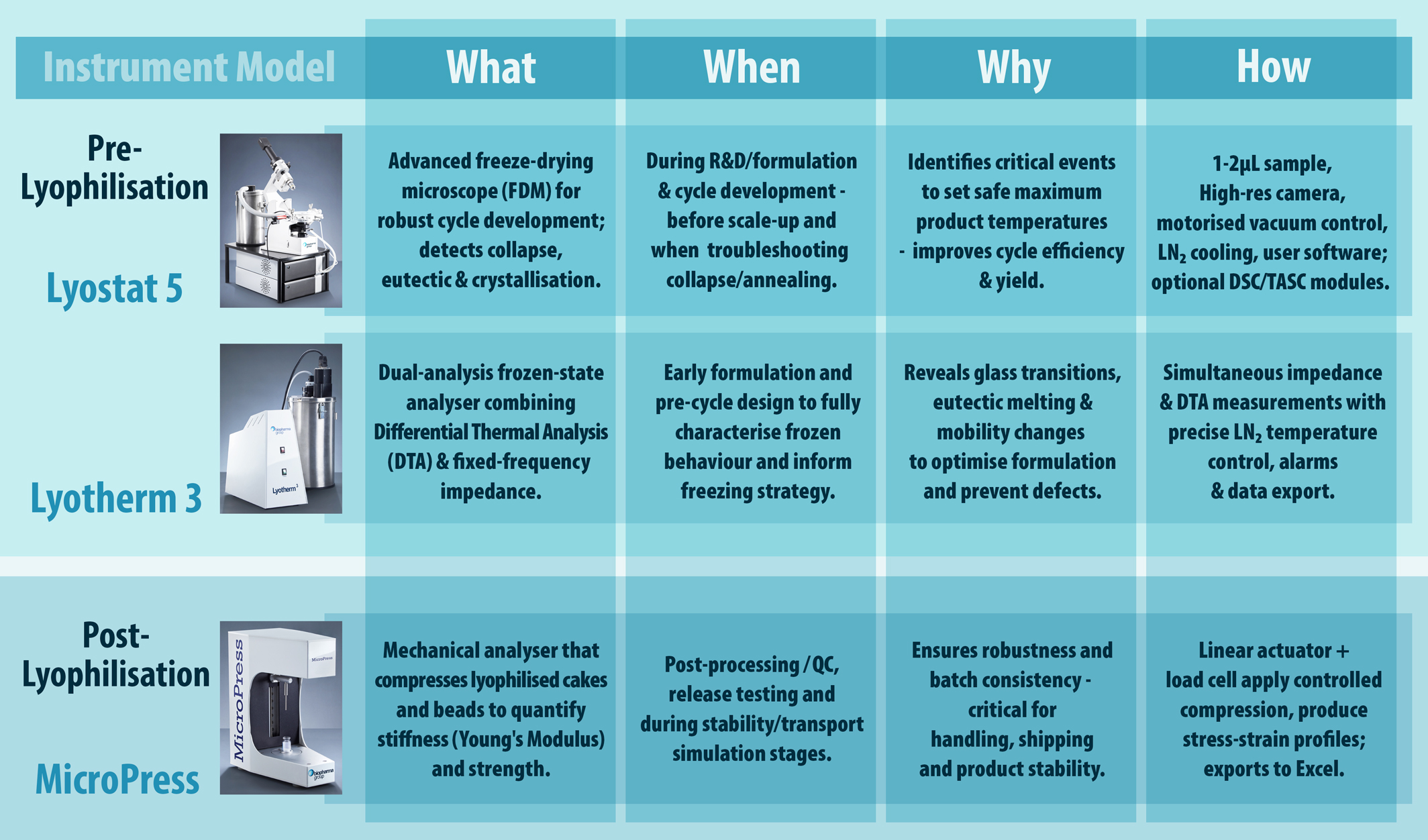

Designed and developed by in-house specialists for easy, practical use, Biopharma Group’s analytical lyo instruments enable you to gain these data insights to the highest levels of accuracy. Throughout the pre-lyophilisation analysis phase, our Lyostat 5 freeze drying microscope allows you to complete precise freeze dry microscopy (FDM) for robust cycle development. Biopharma Group’s Lyotherm 3 analyser also plays a critical role in this process, providing you with an in-depth understanding of your product’s frozen-state behaviour, while helping to prevent defects.

During the post-lyophilisation phase, the MicroPress technology grants the ability to verify the strength and stability of your product. This ensures that it is ready for handling, shipping and deployment.

Biopharma Group’s lyophilisation instruments remove the guess work across all phases of the freeze-drying process. Investing in our analytical lyo instruments provides a 360° view of your formulation’s performance, enabling you to create stable, consistent and future-ready products.

A Lyotherm 3 frozen-state and low temperature analyser enables you to fully characterise the behaviour of your formulations, allowing for the optimisation of your freeze-drying strategy.

A Lyotherm 3 frozen-state and low temperature analyser enables you to fully characterise the behaviour of your formulations, allowing for the optimisation of your freeze-drying strategy.

As a post-lyo analytical instrument, our MicroPress mechanical analyser allows you to compress lyophilised cakes and beads to quantify their strength and stiffness. This enables you to have full confidence in the quality, robustness and batch consistency of your freeze-dried or liquid formulations.

As a post-lyo analytical instrument, our MicroPress mechanical analyser allows you to compress lyophilised cakes and beads to quantify their strength and stiffness. This enables you to have full confidence in the quality, robustness and batch consistency of your freeze-dried or liquid formulations.